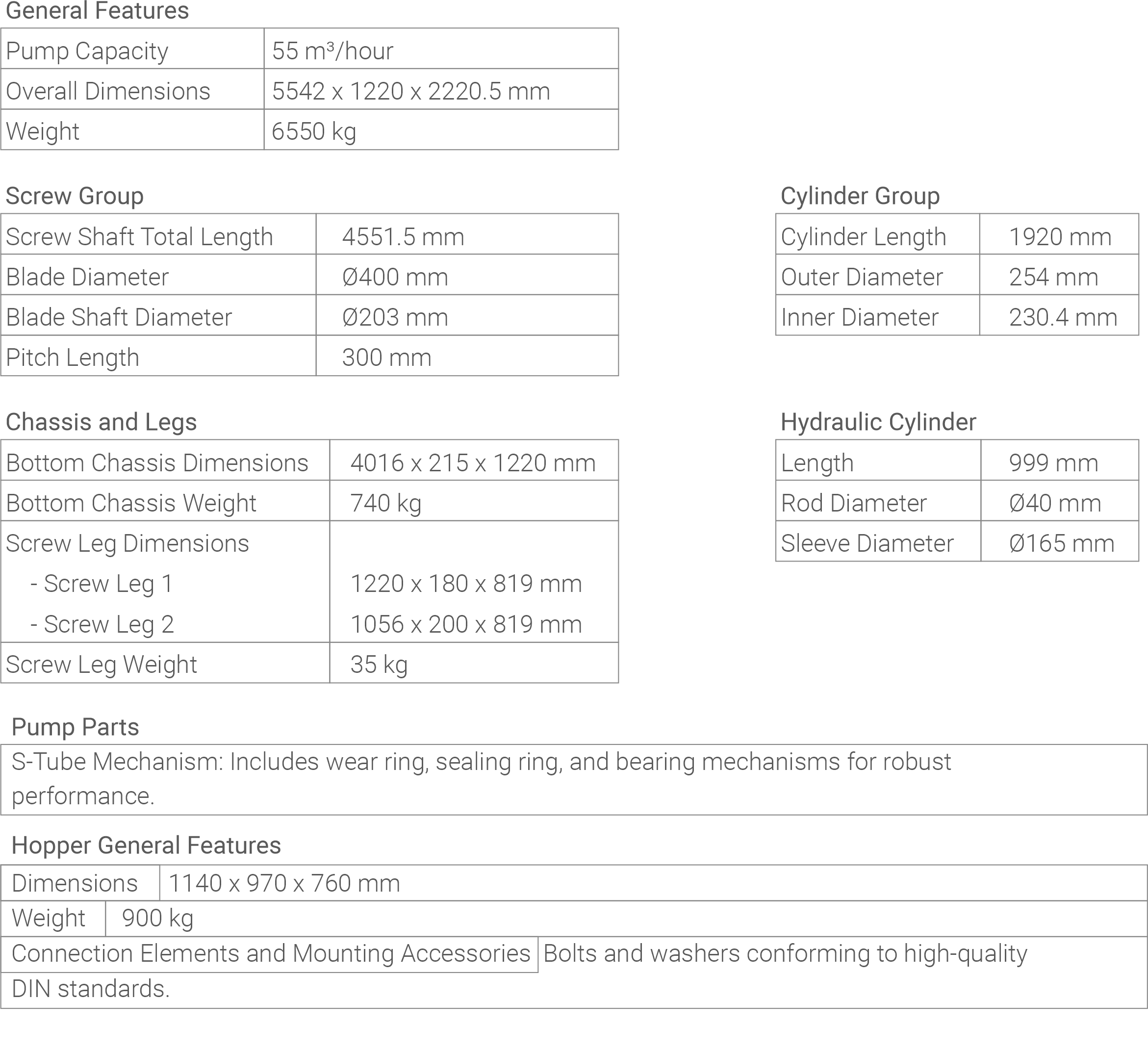

BCP SW55

sustainable power for cleaner feature

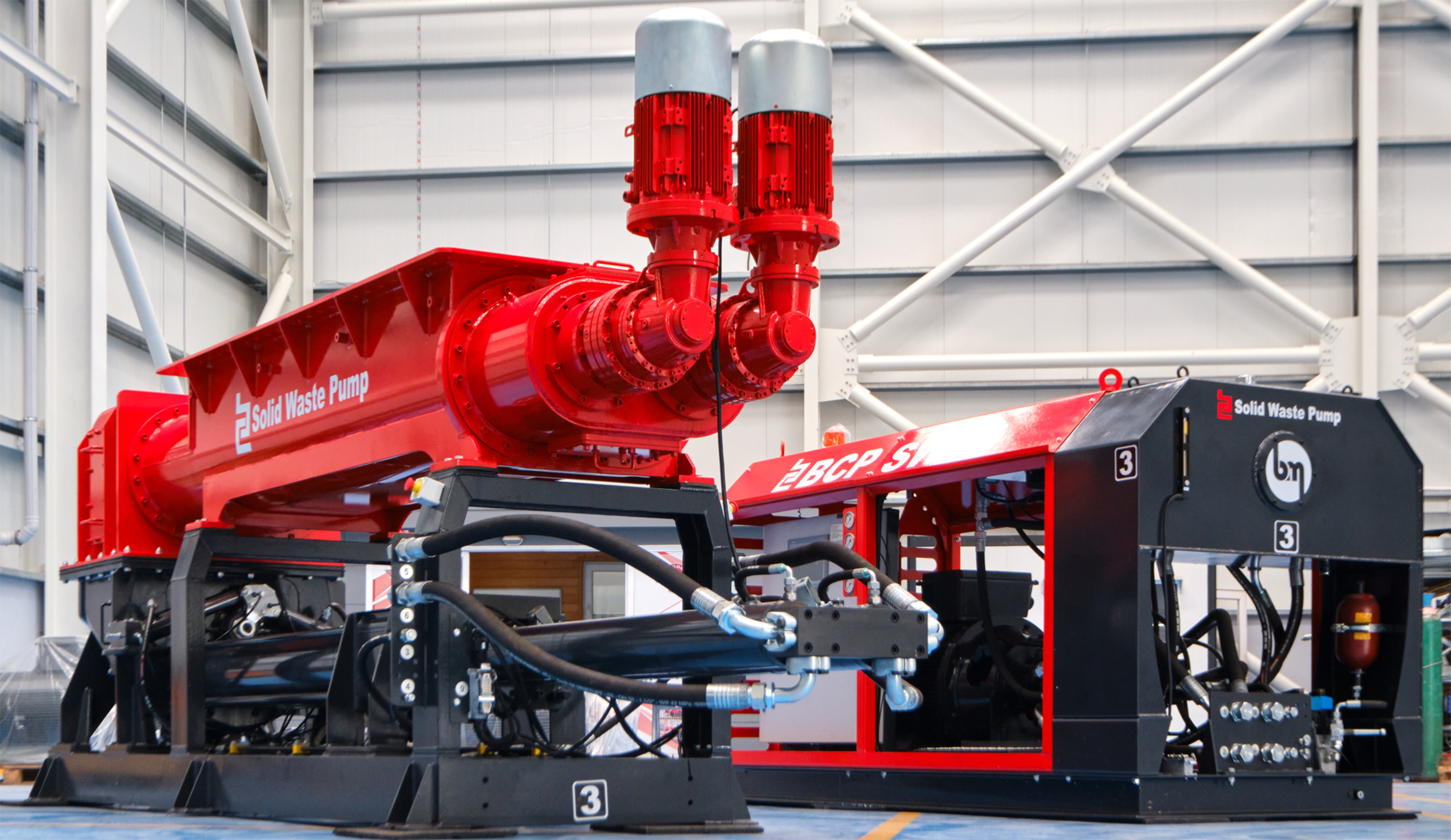

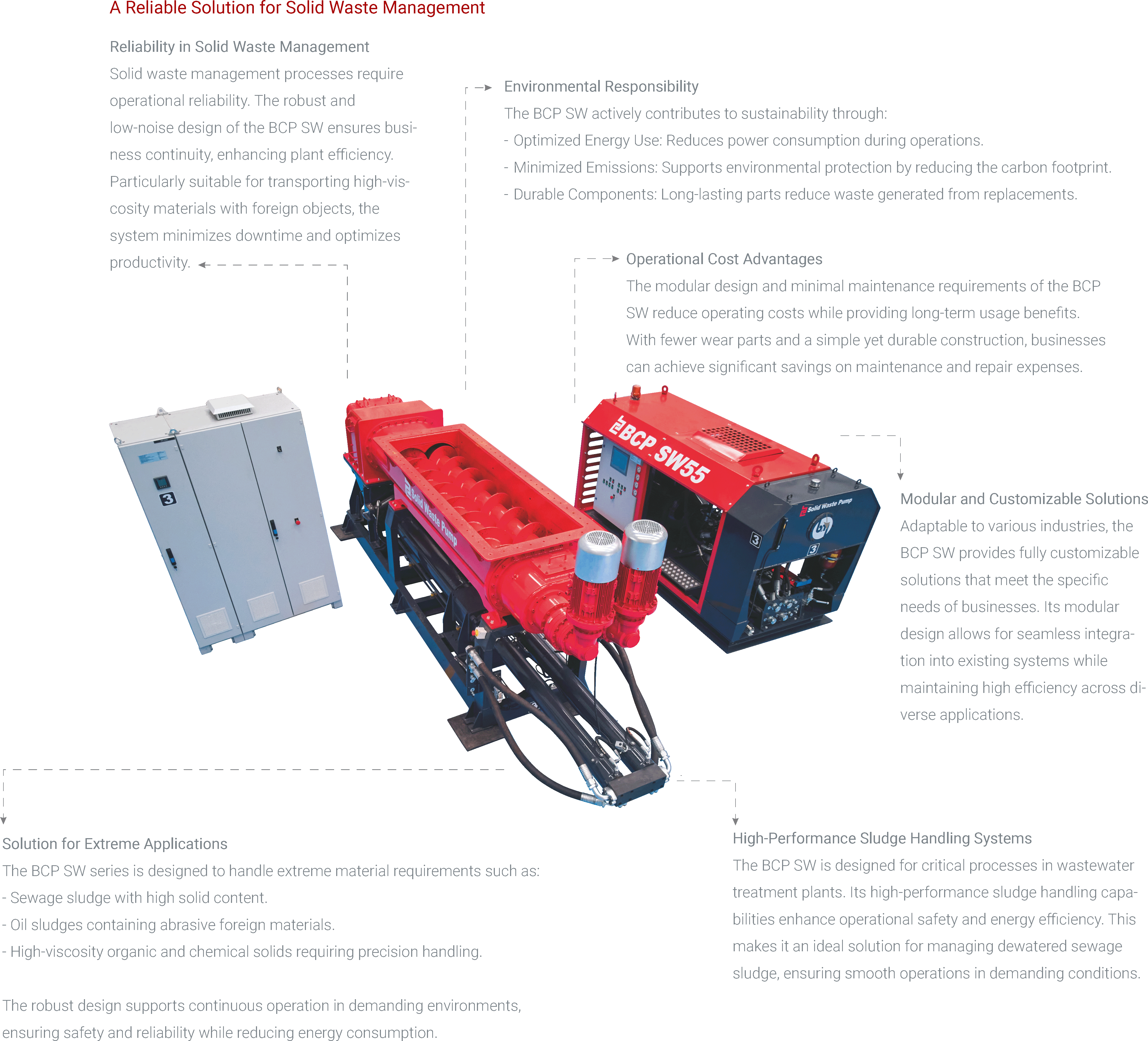

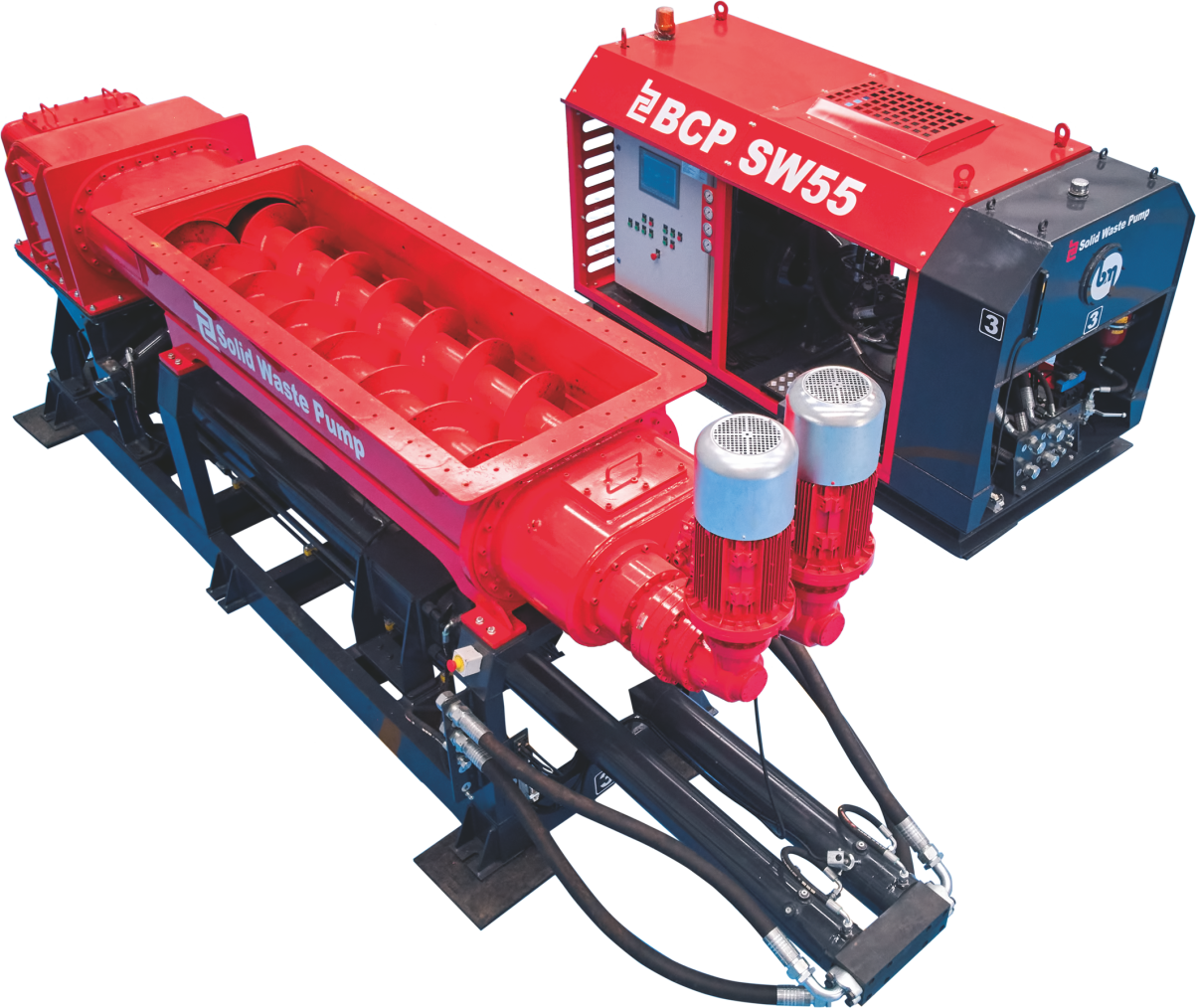

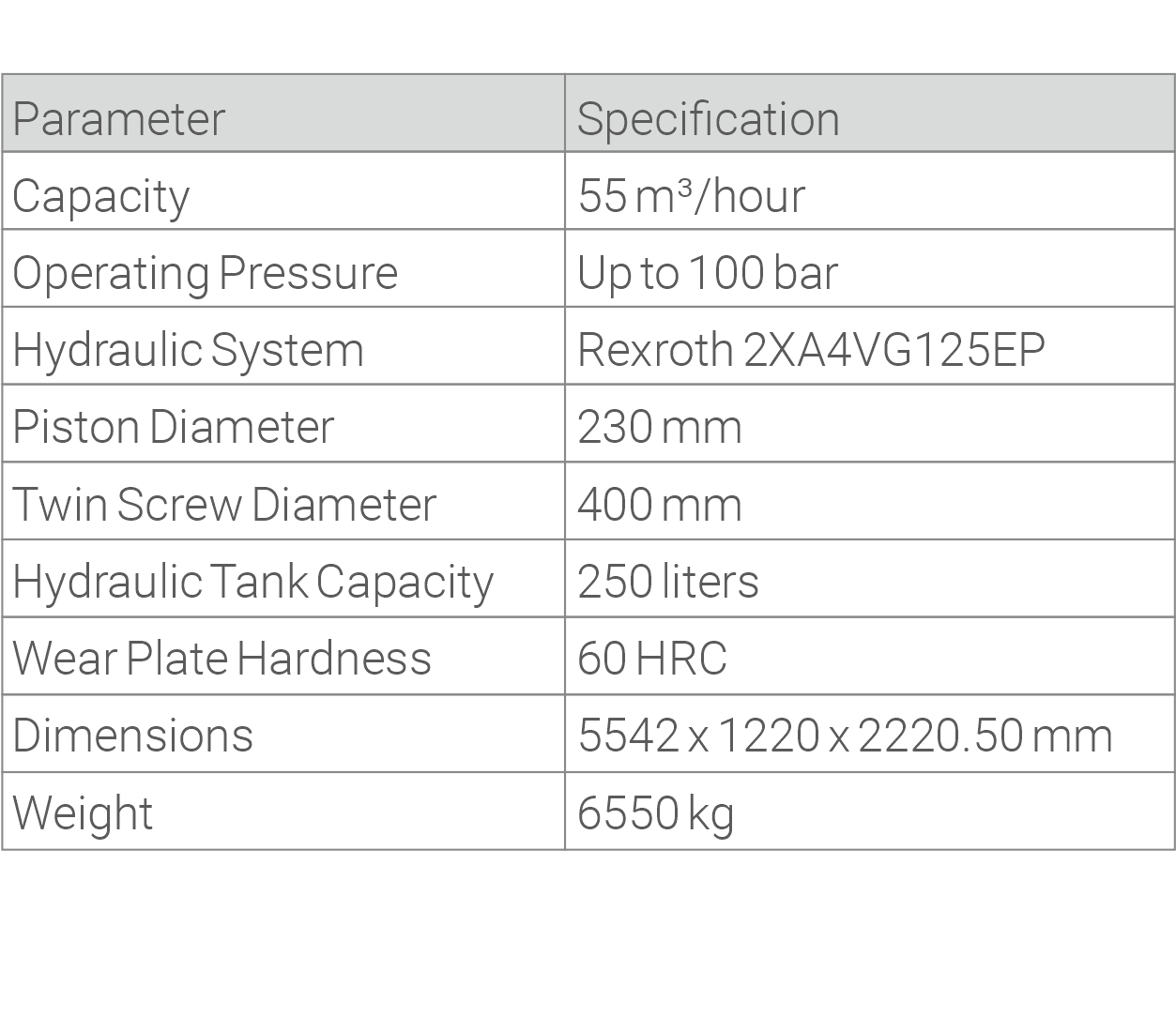

This system ensures operational safety and energy efficiency across diverse industries, such as wastewater treatment, biogas, power generation, and mining operations. The BCP SW sets a new standard with its robust design,

wear-resistant components, and adaptability to extreme operating conditions.

Key Features

1. S-Tube System for Material Flow: Allows uninterrupted transportation of challenging materials without blockages.

2. High-Pressure Performance: Delivers up to 100 bar of pressure, suitable for long-distance and vertical pumping.

3. Low Maintenance Design: Engineered for minimal downtime, reducing operating costs.

4. Energy Efficiency: Optimized hydraulic system minimizes energy consumption while maintaining peak performance.

5. Wear Resistance: Features ST52 steel components and hardened wear plates with 60 HRC hardness.

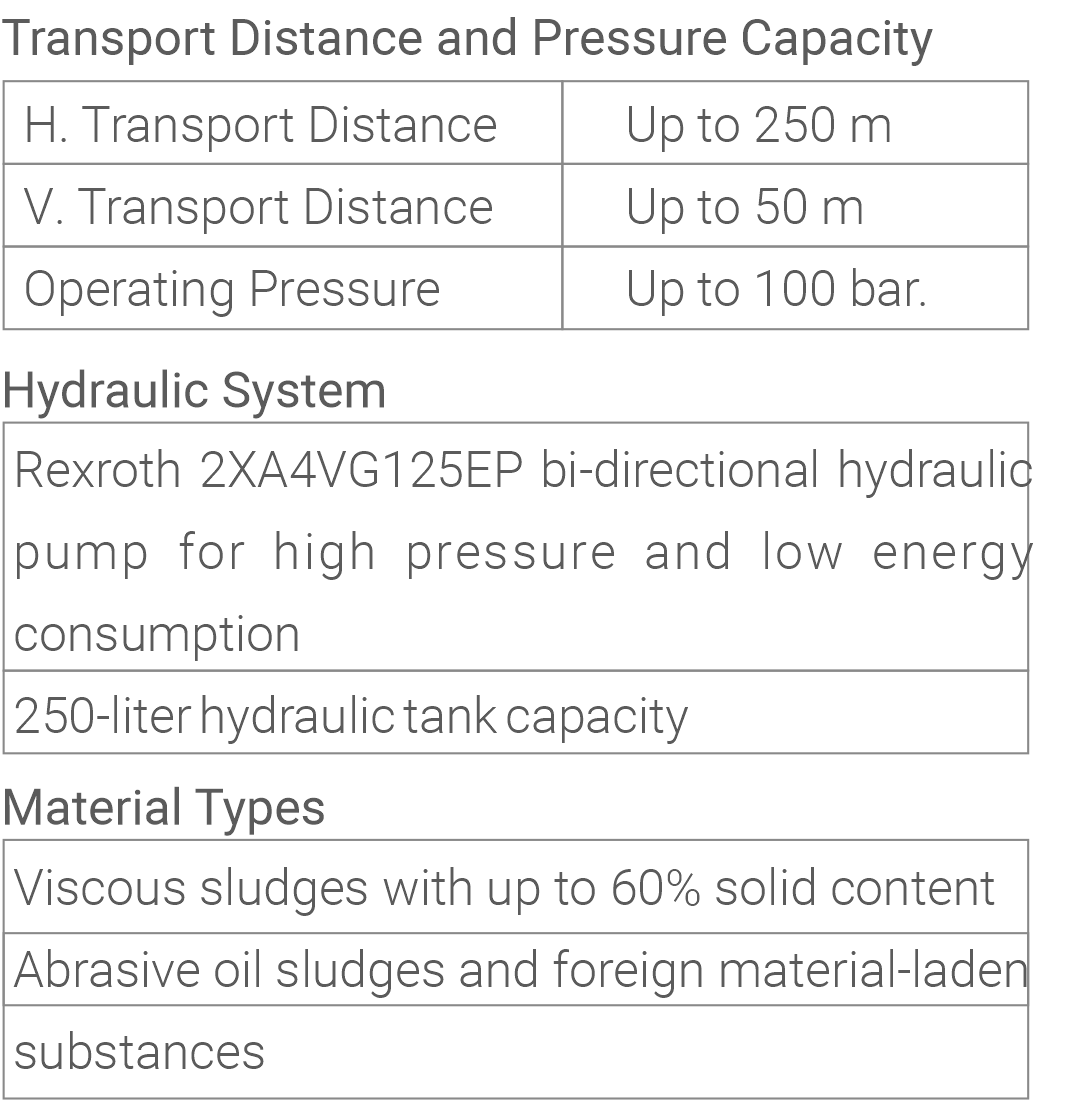

Expanded Technical Details

|

Technical Details |

Technical Highlights |

|

|

|

|

||

|

|

|

|

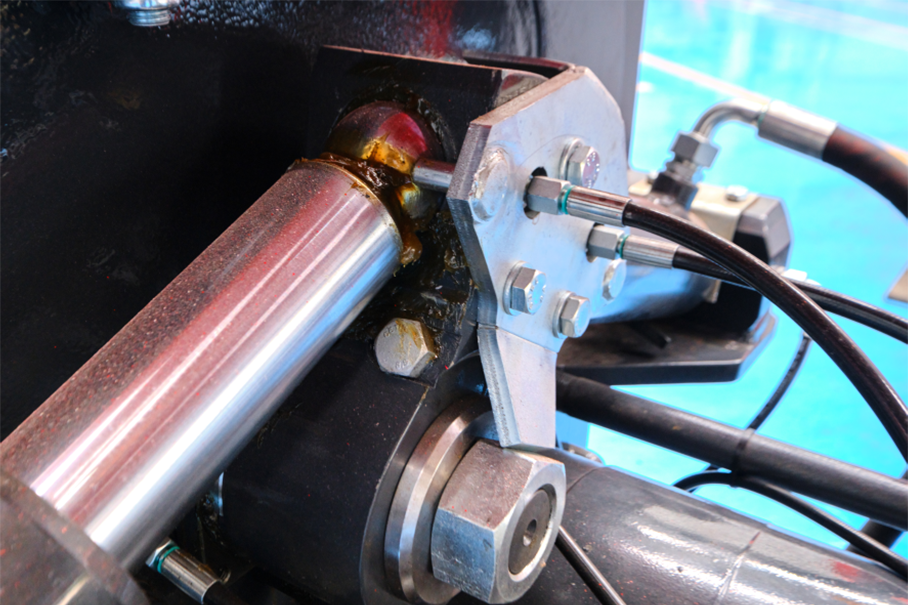

Lincoln automatic lubrication System lubricates the S valve bearings and the spherical bearings of the S valve cylinders automatically. |

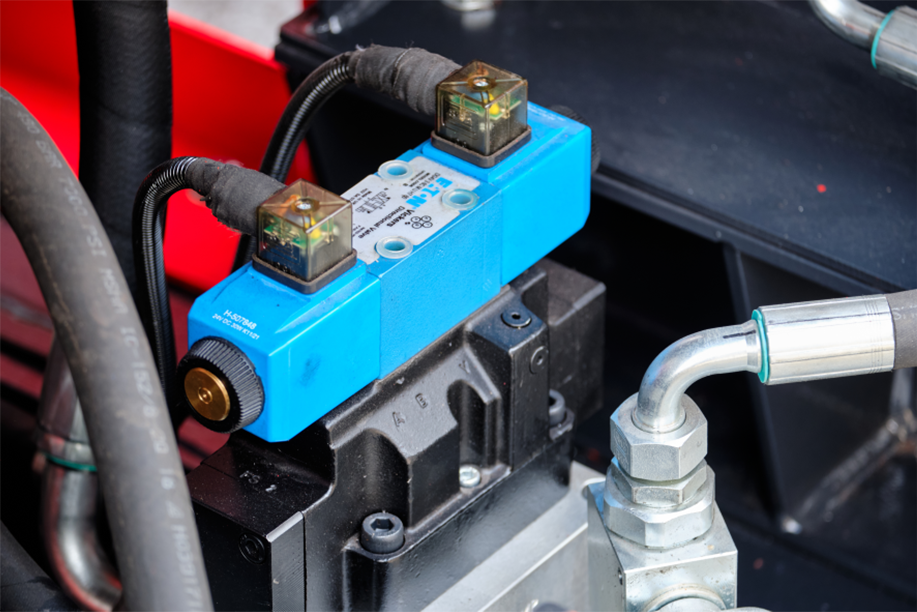

S valve cylinders. | S valve hydraulic control block. |

|

|

|

|

|

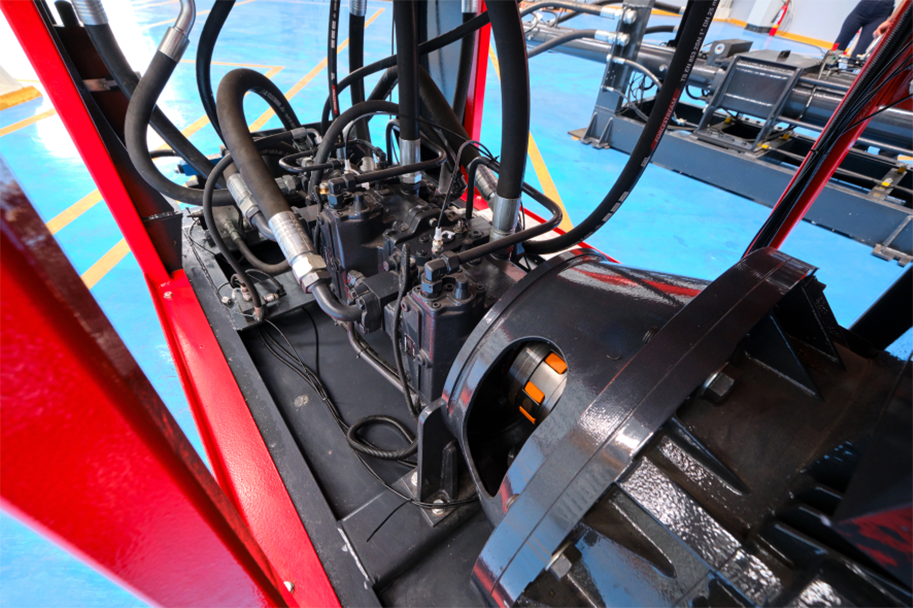

Auger reducers driven by a PDS |

Pumping group PLC control panel. | Hydraulic pressure gauges. | Main power supply electrical panel. |

|

|

|

||

|

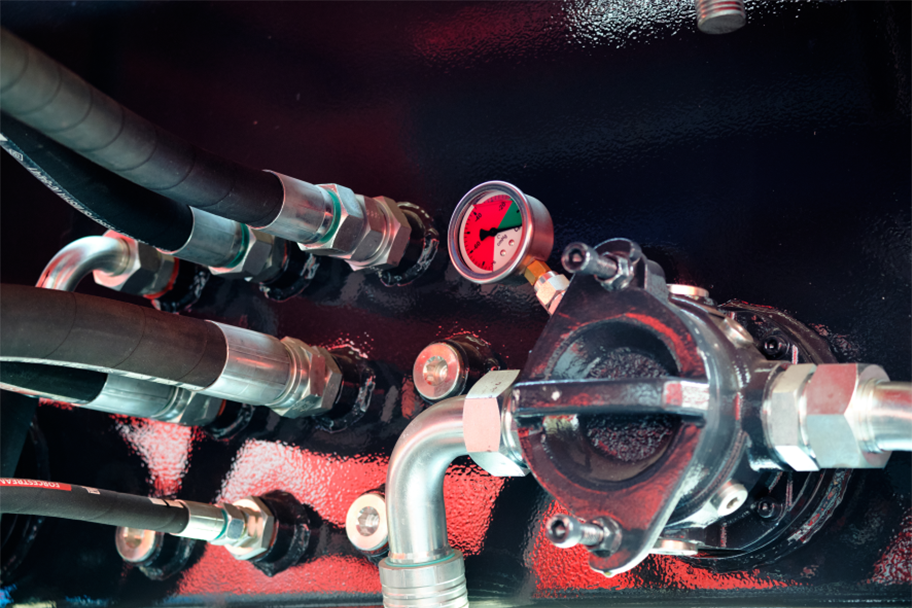

Hydraulic pump suction filter housings and vacuum gauges mounted on the hydraulic tank. If the hydraulic filters become dirty, the vacuum gauges rise, indicating a vacuum in the filter, which helps us detect filter contamination. |

Hydraulic pump group consisting of 2* Rexroth A4VG 125 EP closed circuit pumps and an A10 VO 28 S valve pump. |

Drivers (inverters) for the electric motor powering the hydraulic pumps and auger reducer motors. |

With cutting-edge engineering, the BCP SW series is designed to handle the efficient and reliable transport of demanding materials.

Its advanced system enhances safety, durability, and energy efficiency, making it an ideal solution for industries such as wastewater treatment, biogas production, power plants, and mining.

Built for high-performance operation, the BCP SW series stands out with its rugged construction, wear-resistant components, and adaptability to the toughest environments, ensuring long-term reliability in challenging applications.

Applications

BCP SW is ideal for handling materials with extreme requirements, including:

- Highly Dewatered Sewage Sludges: Efficiently transports high-viscosity sludge, even with high dry matter content.

- Oil Sludges with Foreign Materials: Ensures smooth and reliable operation, even with abrasive and foreign components.

- Biowaste and Organic Solids: Processes high-viscosity materials used in biogas facilities and organic recycling centers.

- Fly Ash and Bottom Ash: Reliable transportation of ash from power plants under high-pressure conditions.

- Mining Tailings: Robust design supports continuous operation in mining and tunneling environments.

- Chemical and Hazardous Solids: Tailored for handling complex chemical compounds and hazardous materials.

|

|

|

||

|

Tailings transport in mining |

Bio-waste and special waste | Fly and bottom ash |

|

Intelligent Control for Superior Management Monitor and Optimize All Processes in Real-Time BCP SW solid waste pump systems are designed to enhance operational efficiency and ensure safe working conditions with advanced control mechanisms. The management system continuously monitors hydraulic pressure, flow rate, temperature fluctuations, and pump stroke durations, ensuring optimal performance. Dynamic Adjustment Management: Optimize pump speed and pressure limits in real-time. Performance-Optimized Calibration: The system allows calibration adjustments to maximize efficiency. Preventive Maintenance Alerts: Uses sensor data to predict maintenance needs and notifies the operator. BCP SW’s intelligent control reduces manual workload while increasing operational safety, ensuring pumps operate at peak efficiency.

|

|

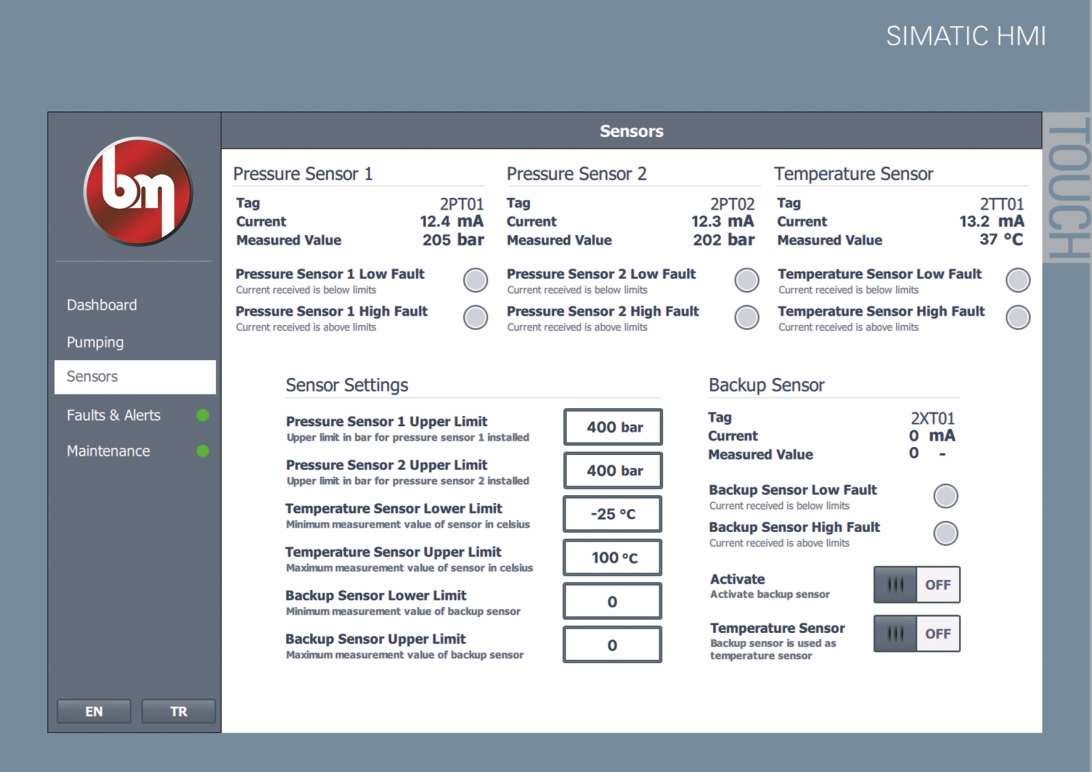

Reliable Sensor System for Continuous Operation Real-Time Sensor Tracking for Maximum Safety In industrial environments, sensor monitoring systems play a crucial role in operational safety. The pressure and temperature sensors continuously track system conditions and notify operators of any irregularities. Instant Sensor Tracking: Displays real-time pressure and temperature values, along with potential faults. Defined Upper and Lower Limits: Operators can set threshold values for automatic system protection. Backup Sensor System: If a fault occurs in the primary sensor, the backup sensor is activated, ensuring uninterrupted operation.With precise sensor monitoring, you achieve maximum safety and uninterrupted performance!

|

|

|

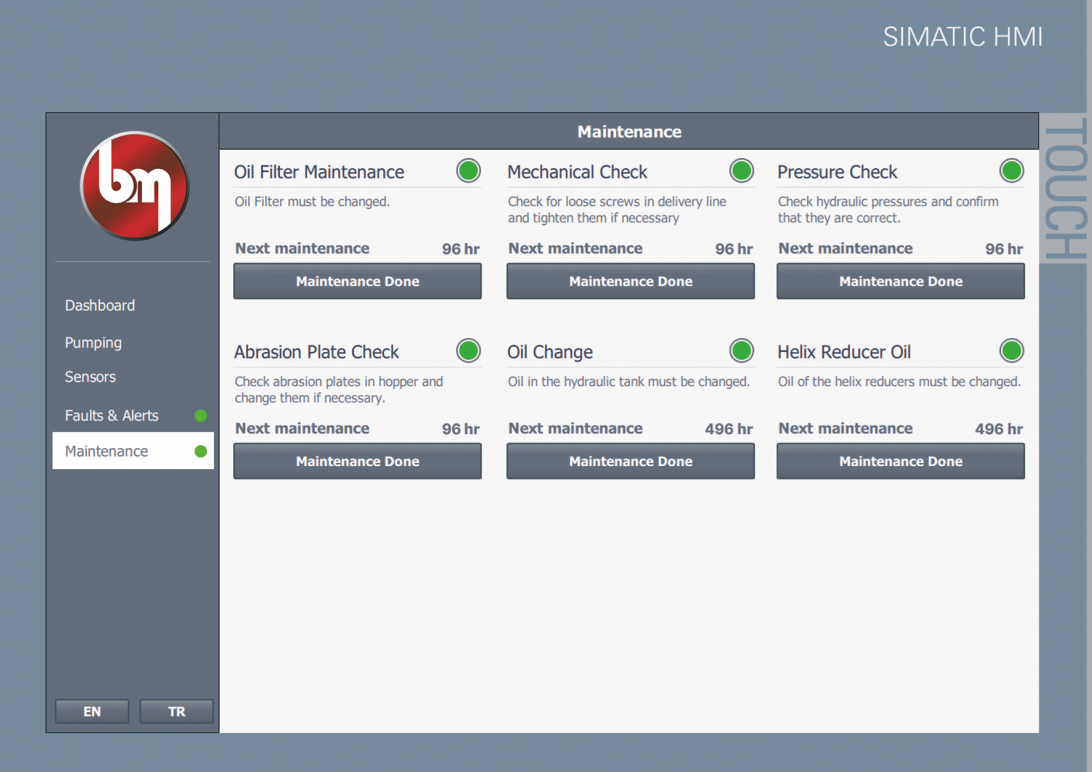

Smart Maintenance Management for Minimum Downtime Preventive Maintenance Tracking for Uninterrupted Operations The Simatic HMI maintenance module ensures optimal system performance by automatically tracking operating hours and sending scheduled maintenance notifications. Oil Filter and Hydraulic Oil Replacement: Notifies the operator when service is due based on operating hours. Abrasion Plate Replacement Alert: Provides time-based notifications to inspect and replace abrasion plates if necessary. Helix Reducer Oil Change Reminder: Alerts the operator when the reducer oil needs to be changed after a set number of operating hours. Mechanical Inspection Reminders: Periodically notifies operators to check bolt tightness and connections for secure operation.Scheduled maintenance ensures long-term reliability and reduced downtime! |

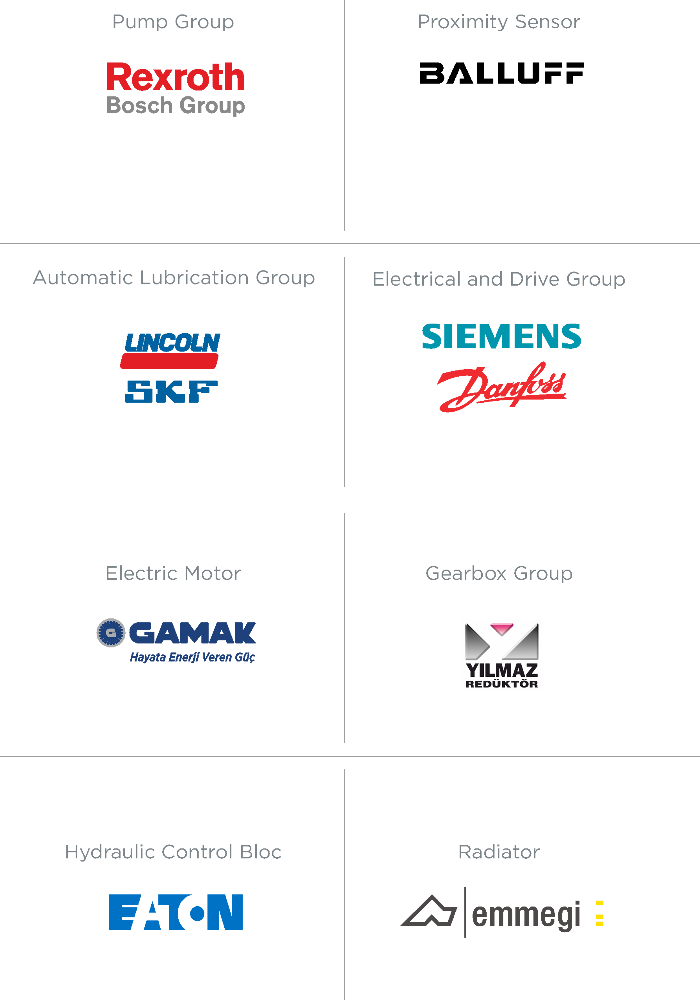

Origin Of Product Used

Our organization collaborates with corporations that possess deep-rooted expertise and are recognized as top-tier entities within their respective industries. We hold the belief that their unwavering dedication to quality is a vital contributor to the added value of our goods and services.

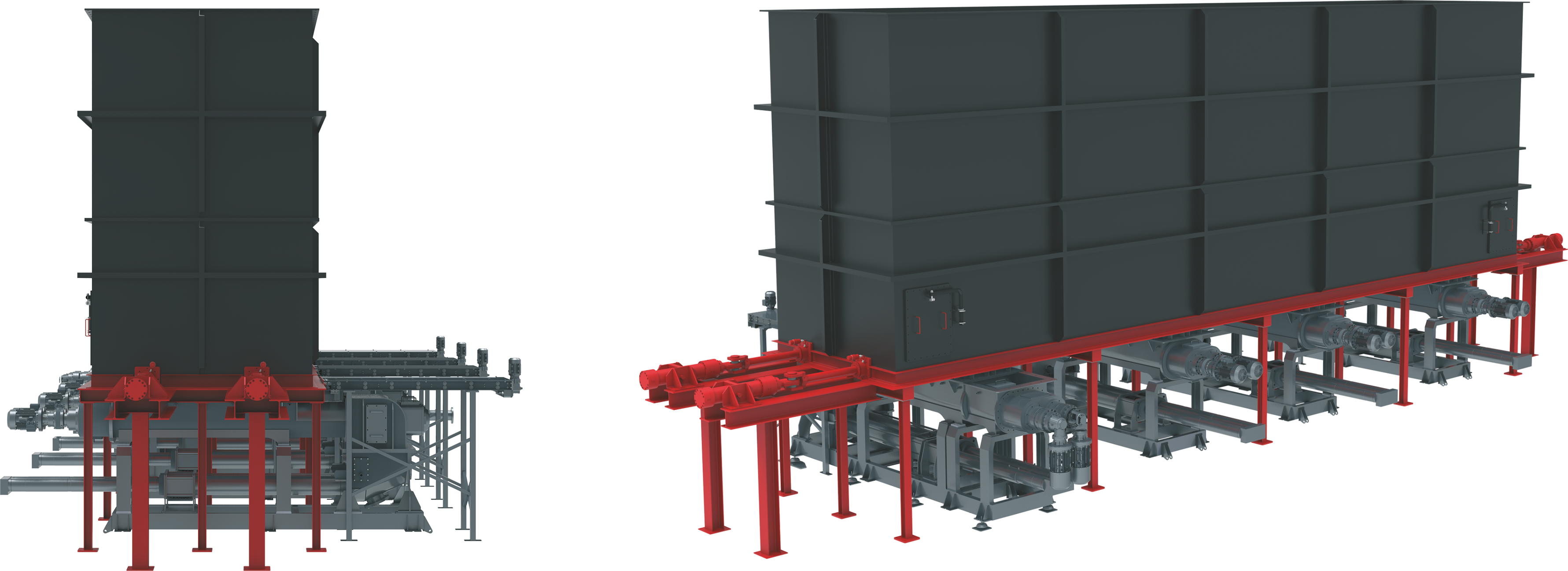

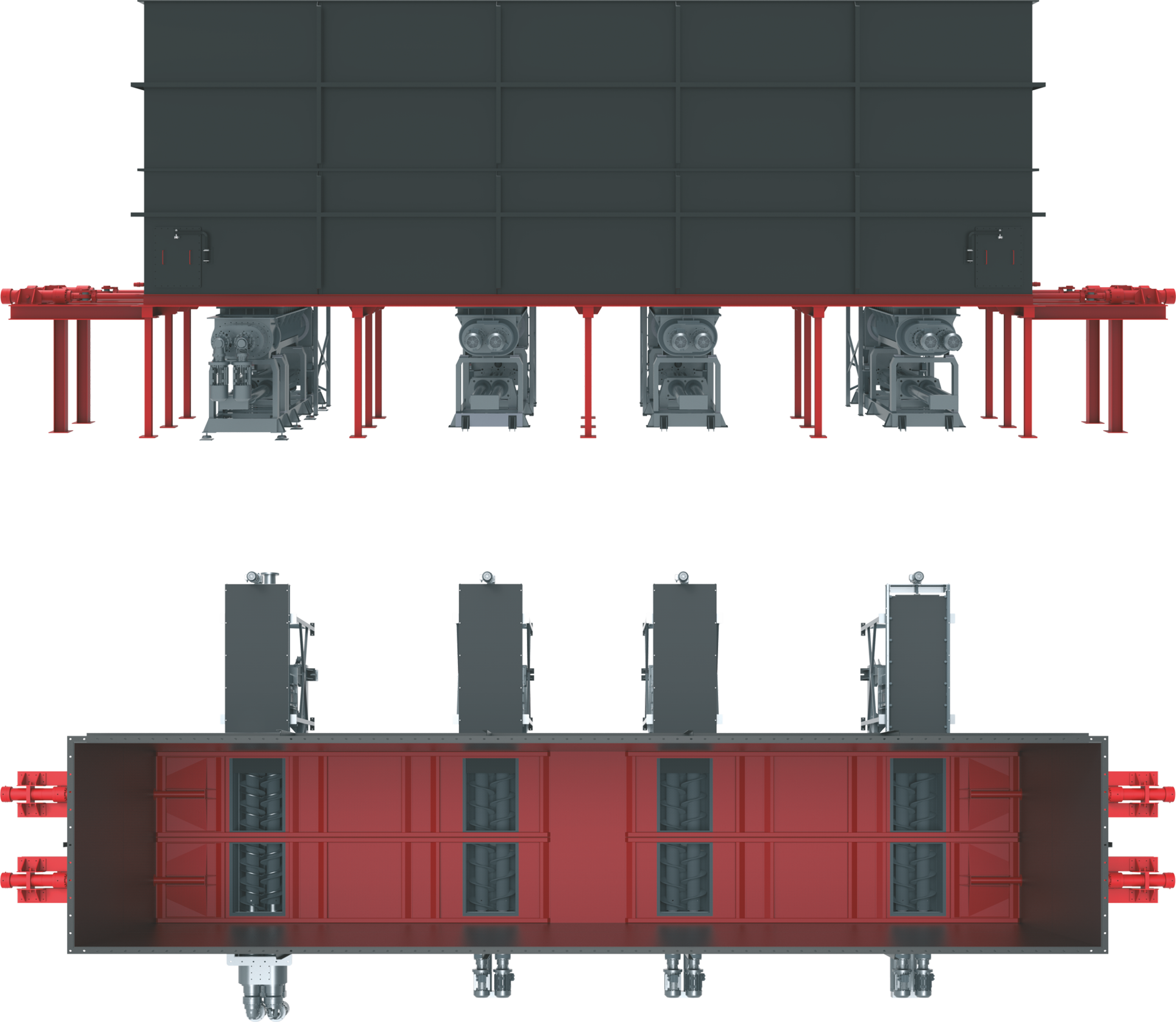

Bunker Operating Principle

Bunker Feeding System:The bunker lid operates hydraulically, opening and closing automatically. As a truck approaches the bunker filling corridor, proximity sensors positioned in the corridor trigger the hydraulic system, ensuring that the lid opens automatically and remains open until the waste discharge process is complete. Once the truck leaves the corridor after unloading, the lid automatically closes again.

Bunker Discharge System

Due to its highly dense and sticky consistency, the waste stored in the bunker cannot naturally flow into the screw feeder by gravity alone. Initially, a small amount of waste will enter the screws during the first discharge, but over time, bridge formation will occur, blocking the flow and disrupting the system. As a solution, a hydraulically driven scraper installed at the bottom of the bunker continuously directs the waste toward the screws mechanically, ensuring the system operates smoothly and without interruption.

Warrant Policy

| Boom Makina guarantees that all its products are free from any manufacturing defect and sub-standard workmanship. |

| Whereas in case any manufacturing defect or non-performance of the machine is reported, BM assures that it would take all possible steps to correct the problem immediately by repairing or by replacing the defective part free of cost. |

| The assurance of a warranty is valid for a period of 12 months from the date of commissioning of the machine. |

| Claims for warranty will not be applicable for delivery line equipment, electric or electronic items. |

| Warranty would cease in case the machine is put to use for purposes other than those for which it has been manufactured. |

| Damages or failure of parts occurring due to improper maintenance/operation, mishandling, accident, etc, are not covered under warranty. |

| Any claim for warranty would be considered only based on inspection of the broken down machine by BM's Service Engineer and his subsequent report thereon. |

| The policy of warranty is applicable only for those machines which are directly purchased from BM, and the warranty would cease in case of resale of the machine to a third party. |

| Warranty for the items replaced 'under warranty' is valid from the date of fitment till the original warranty period of the machine. |

| The defective spares which are replaced under warranty become the property of BM, and the same will have to be returned to the BM factory by the customer by normal mode of transport. If not returned, BM would raise an invoice for the items replaced under warranty. |

| In case of all replacement, freight and costs incurred for clearance of the imported materials, if any, are to be borne by the customer. |

| BM reserves the right to accept or reject any claim under warranty without citing any reason whatsoever. |